Project identification number: 2020-1.1.1-KKV-START-2020-00063

ARTRADE Ltd flexibly automates the handling and assembly of injection molded parts through industrial robot and 3D object recognition technologies

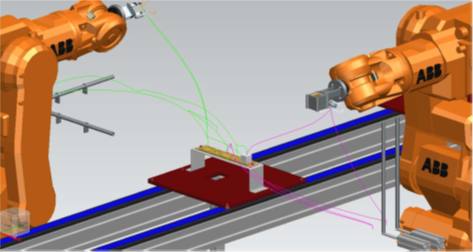

The aim of the project is the flexible automation of the handling and assembly of injection molded parts using industrial robot and 3D object recognition technologies at ARTRADE Kft.

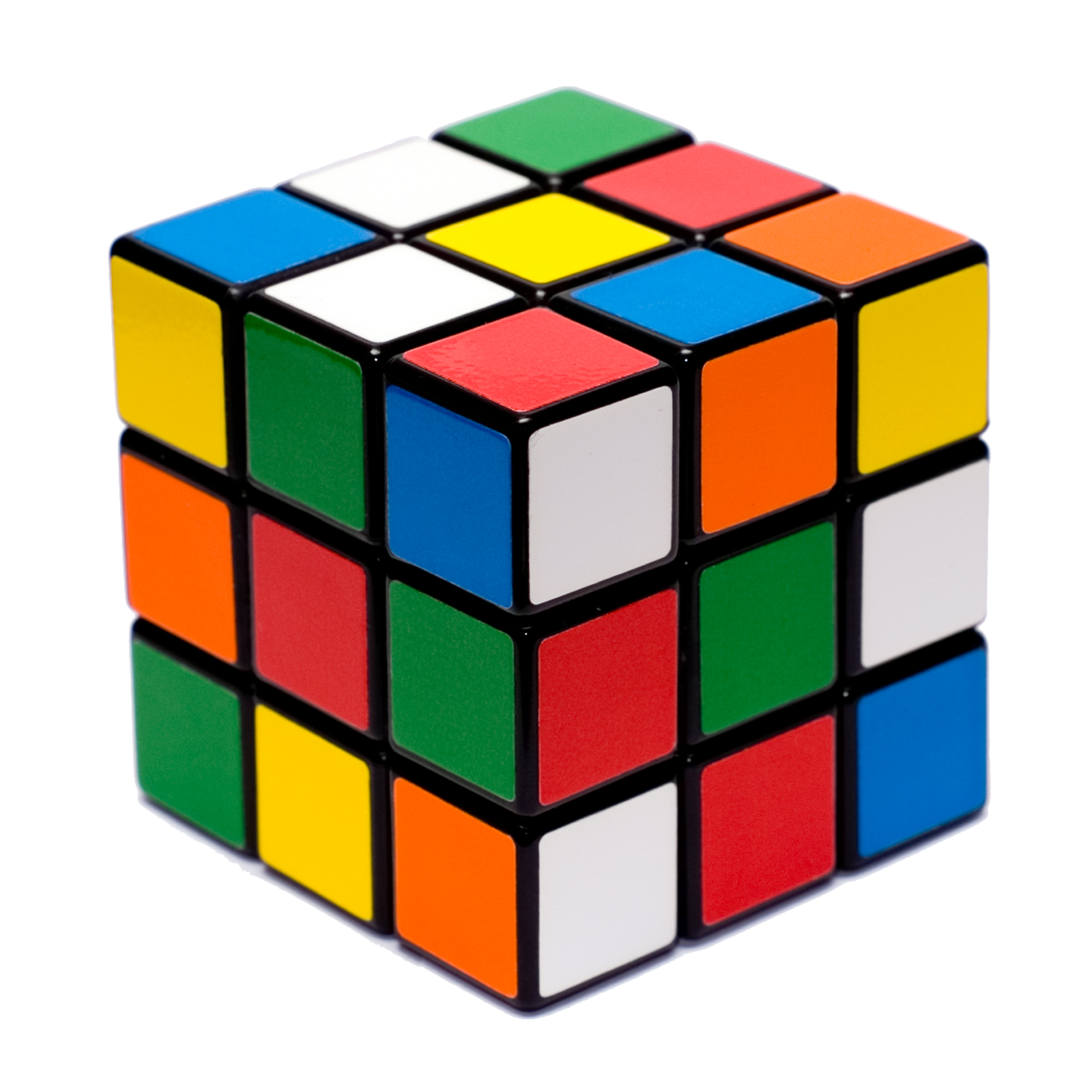

ARTRADE Ltd. plays a significant role in the field of logic games among domestic and international development and manufacturing companies. In domestic production, toys are assembled manually, in which technology can respond to rapid market expectations, enhance productivity and meet with the high-quality requirements expected on the world market, only with increased labor work input.

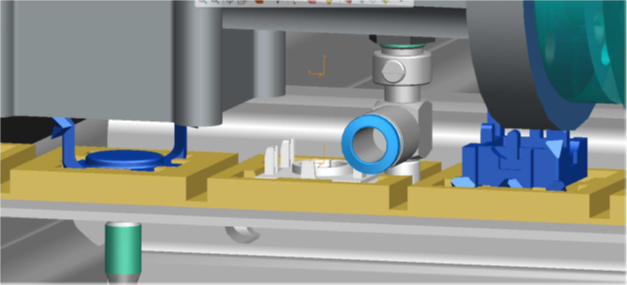

ARTRADE Ltd. has a new European 3D Trademark (Registration number: 016999286) with a magnetic, multifunctional spatial logic game, that product according to a market survey, has a hundred thousand pcs market demand per year. Further, market expectations force the assembly of finished products made of polymer parts not larger than the matchbox produced in our injection molding plant, and a small proportion of non-polymer parts supplied by other partners, typically finished products assembly of 10-50 pieces, has to be flexibly automated from production equipment to quality control and implemented in a short time.

We decided to move forward in our developments from manual and purely mechanically automated material handling and assembly to IPAR 4.0-based technologies such as industrial robotics and machine image processing technologies that use artificial intelligence in one of the most productive ways.

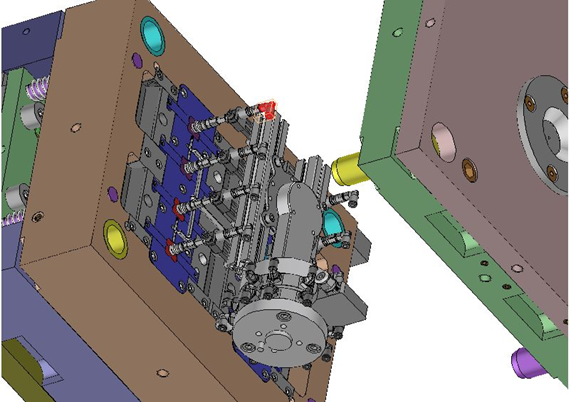

Using the planned innovation, we can switch from one product production to another product production in a short transition time. Our production system can be adapted very quickly and cost-effectively to the rapid product upgrades in the toy industry, and the development costs of the production system are lower compared to the rigid automation target machines, using the virtual commissioning technology.

A special technological challenge is that the differences between injection molded parts (eg lower housing, upper housing, right-to-left) are sometimes so small that it is not possible to distinguish between these parts by manual methods or mechanical machine methods, quasi, these parts have to be under control from the production equipment. This requirement also expects the use of IPAR 4.0 technologies.

ARTRADE Kft. Uses a 3D prototype printer in its product development processes. We consider it as a human innovation to use our extensive 3D printing experience in certain components 3D printing of material handling and product assembly systems.

Based on the tender expectation, the innovation planned in our application belongs to the category of “c) prototype, product, technology, or service that can be considered as a novel and commercially effective at least at the enterprise level”, within the “technology” sub-case.